Apple Rethinks Its Relationship With China

The iPhone maker is planning to move much of its manufacturing operations out of the country in the coming years.

(You’ll find the text version below this embedded video)

Apple is rethinking its relationship with China—and that’s really bad news for China’s position as the “Factory of the World.”

China has been in turmoil recently as Covid cases in the country surge despite harsh lockdowns and other restrictions. That’s led to unrest across the country and the largest protests in over three decades.

One place where this unrest has been extremely visible is in iPhone city, a massive facility that employs and houses up to 300,000 workers who assemble iPhones for Apple.

That facility, which is owned by the Taiwanese company Foxconn, was the site of a Covid outbreak in October and November.

This article goes in depth into some of the crazy things that happened at iPhone city recently.

To keep the factory in iPhone city running while adhering to China’s zero-Covid policies, Foxconn and local authorities essentially cut off the facility and its hundreds of thousands of workers from the outside world.

Many workers spent weeks living in forced isolation in dirty dormitories, subsisting on very little food.

“The cooked food often ran out, leaving many with only bread and boxed milk. Those who didn’t go into the factory—because they were sick or quarantined in their rooms—at times didn’t get anything, according to people who were at the complex at the time.”

To make a long story short, eventually these horrible conditions and a dispute about pay led to violent protests at the facility. Thousands of workers ended up running away, and even though Foxconn has since made amends by offering bonuses to some of the workers, iPhone city still hasn’t fully recovered.

The factory is currently operating at 30-40% percent of its capacity.

As you would expect, that has led to a significant reduction in the production of iPhones.

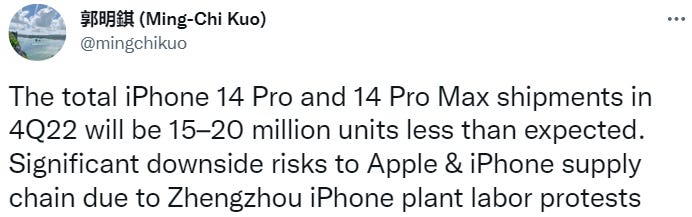

According to analyst Ming-Chi Kuo, iPhone shipments in the fourth quarter of this year are likely to be around 70 million to 75 million units, which is 15-20 million fewer units than was expected before the iPhone city debacle.

Consumers who want a new iPhone have to wait several weeks longer than they normally would to buy one, and rather than wait, some of them are opting to purchase competing phones instead.

Big Changes

Unsurprisingly, Apple hasn’t been happy about this. The company has been quietly watching all of these events unfold and word is, it might be ready to make some big changes.

China was supposed to be a stable place to do business—and for much of the past few decades, it has been. But ever since 2020, China’s reputation as a stable, predictable manufacturing center has been called into question.

A once predictable environment has turned unpredictable as factories are shuttered on short notice, leading to uncertainty and instability in the country’s manufacturing industry.

So now Apple is rethinking how reliant it wants to be on China.

The company is reportedly considering moving a lot of its manufacturing out of China and into places like India and Vietnam.

According to Ming-Chi Kuo, Apple and its partner Foxconn are hoping that in the future, India can handle 40-45% of iPhone production, while Vietnam can manufacture a lot of Apple’s other products like AirPods and laptops.

Currently, Apple produces well over 90% of its products in China, so this would be a dramatic shift.

Shifting Views

Apple isn’t alone in rethinking its relationship with China. Other companies are also wondering whether they have become too reliant on the country.

China’s stringent zero-Covid policies have brought this issue to light, but even if those policies end—which they probably will one day—the damage has already been done.

Companies now realize that they shouldn’t be dependent on a single country for their manufacturing needs—especially a country that could be considered an adversary.

You could even argue that these feelings started to emerge before Covid. In 2018, the Trump administration in the U.S. kicked off a trade war with China. Since then, the economic conflict between the two countries has escalated, adding another layer of risk for companies that depend on China.

The potential for Western countries and China to some day fight a war over Taiwan has also contributed to worries about being overly-reliant on China.

Together, all these concerns have kicked off a trend known as friendshoring, or the process of bringing supply chains back to a company’s home country or to other friendly countries.

A Tall Order

Shifting away from China is no easy ask. In 2021, China was home to 28% of the world’s manufacturing, almost as much as the U.S., Japan and Germany combined.

That didn’t happen by chance. China has spent decades fostering the perfect environment for manufacturing.

From a comprehensive transportation system, to an extensive network of factories, to a massive and inexpensive labor force, China has had all of the ingredients necessary to be a manufacturing powerhouse.

So while countries in Southeast Asia and South Asia are rapidly building their manufacturing capabilities, recreating that perfect environment is a tall order.

But regardless of how difficult it will be, if Apple is seriously talking about shifting manufacturing outside of China, then you have to believe that it could happen. And if other companies follow suit, then China’s share of global manufacturing could start to decline.

That doesn’t mean China is going to stop being the top manufacturer in the world anytime soon. The country still has the world’s largest population, which will always be there to consume goods made in China.

But we might eventually see fewer “Made in China” products outside of the country.